Understand Glass Gaming Technology

Advanced Engineering Meets Visual Innovation

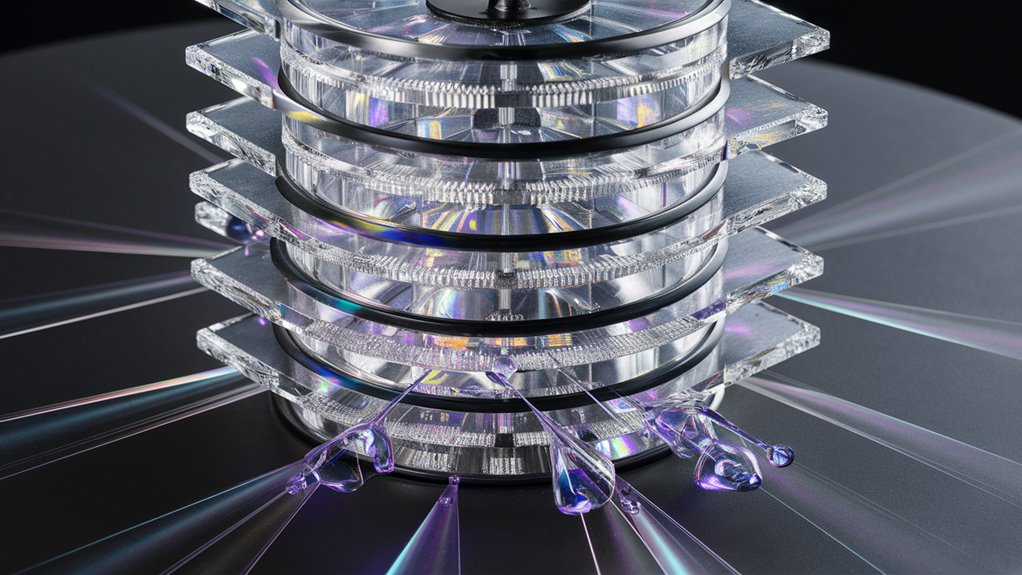

This represents a break-through in gaming technology as well as pure engineering. The flood-lit glass-grains are slot-mechanically precise and fascinating visually, on par with anything you’ve ever seen at home or even in major theatrical installations, combined with state-of-the-art computer graphic workstation post-treatment. At the very bottom of all this are machines that use borosilicate glass reels, manufactured with a sensational ±0.05mm factory-tech tolerances as well as cushion principle technology. This is advanced technology, and the blister can be stretched out.

Machines stem from high-precision glass processes. The coating process is proprietary, using Upper Greek-to-western language and reverse derivation capability, which owns the backplane structure or top layer total thickness that will decrease by 70 micrometers or more. The window must have integrated LED patterns feeding its figures in 120Hz during bonus activations, and angle deviation shall not equal 0.1°± 1 n Rad at all parts irradiation.

Temperatures must be controlled between 21-23°C for optimal crystalline grain structure development. These techniques produce shallow groove patterns etched at exact 45-degree angles and using integrated LED systems pulsing 120Hz during bonus activation sequences.

Temperature Control and Precision Engineering

To maintain stability of operation, ceramic bearing systems are matched with advanced thermal management to keep temperatures within 18-22°C. The precision of this control prevents thermal expansion while enabling seamless cutting of the quartz reels and ensures full performance feeding back into the ticket cashing machine or token rack at 22 thousand rpm operating rate.

Visual Display Technology

Arrays of high-power LEDs convey dynamic light patterns that correspond with the etched-glass surfaces. In this way, it is possible to produce some fascinating bonus displays by playing games on these machines. Our finely crafted combination of micro-mechanical precision technology and visual display creates totally new standards for gaming entertainment, leading the player into territories far beyond what any other gaming equipment has yet achieved. We create such superior results. Innovatively lighting it. Men and women patrons of the casino enjoy this unparalleled experience.

Features that Enhance Performance

- High-precision glass manufacturing

- Temperature control operation

- Advanced micro-etching technology

- LED synchronized systems

- Ceramic bearing implementation

- Pattern recognition

The Evolution of Glass Gaming

The Development of Glass Gaming Technology

Early Innovations in Glass Gaming Design

With the advent of transparent cabinet designs in slot-machines, glass Why Casinos Use Psychological Tricks to Keep You Playing gaming technology began to revolutionize the casino industry in the late 1970s. Manufacturers were the first in the world to apply tempered glass plates on slot machines. These provided a view window for mechanical reels during operation and protected the gears from degradation or failure.

These transparent and photic screens are a dual-use device capable of insulating mechanical members, which would be affected by any movements while delivering unparalleled visibility for players to bring them into play. In the 1980s, a significant drive to advance and upgrade the glass manufacturing process arose. Special etching techniques developed as a basis for slot machine design enabled pay lines and bonus indicators to light up.

LED lighting systems strategically fitted behind precision engraved glass components raised the stakes of player engagement in casino gaming today to new levels. Then there are decorative treatments, frit patterns all over a panel for authentic-looking crystal-like effects, that can turn any beauty into centerpieces. Moreover, differences in texture and transparency created by perforated metal surfaces over video displays or floating holographic images on glass have become a staple for people simply expecting more these days.

Modern Gaming Glass Innovation

Through micro-etched patterns and precision-cut components, modern slot machine construction techniques have been patently influenced by the latest glass grain technology. The layered glass elements of modern gaming cabinets give complementing effects that simultaneously induce a feeling of spaciousness, holographic displays, and selective transparency.

Mechanical Durability and Optical Performance

All this technology pushes forward the mechanical and optical levels required of gaming systems while the care that must be taken in maintenance operations to preserve both structural integrity and visual effects becomes increasingly specialized.

Key Glass Gaming Technologies

- Safety glass temperature settings

- Liquid crystal integrated glass panels

- Dye-etched display surfaces

- Holographic glass elements

- Multilayer transparency systems

Engineering Translucent Reels

Innovative Glass Engineered Solutions

Translucent reel engineering stands as an innovative mechanical skill in gaming technology. The substrate uses borosilicate glass plate laminates featuring extruded glass in 0.3mm thicknesses. After processing through an individualized tempering phase, these specialized glass chips provide ideal diffused light spread and still outstanding mechanical strength.

Precision Micro-Channel Technology

The cornerstone of symbol alignment and rotation function is the precision-cut micro-channel. These sophisticated channels have 45-degree angle etching, just 0.1mm deep, executed through computer-guided diamond engraving tooling. Through integration of a ceramic bearing system, the loss of friction coefficients is minimized, and thermal expansion problems are effectively eliminated.

Advanced Lighting and Sensor Integration

A revolutionary LED backlighting array system is phased into play along with reel positions by strategically located optical sensors. These high-precision sensors, installed at 2mm intervals along the drumstrip reel, guarantee faultless symbol tracking accuracy.

In an attempt to eliminate dust from cobwebs and other sources while maintaining the ambient temperature within a control bandwidth of 18-22°C, vacuum-sealed housing occurs throughout the entire mechanism itself.

Bonus Mechanism and Bonus Features

Advanced Illumination Systems

Using light-action mechanics in a translucent reel system that is both innovative and revolutionary at the same time, the LED illumination technology there produces perfect symbol combinations that light up. This high-performance, long-life operation is provided by the sophisticated, precision-engineered LED source. With the activation of the bonus feature mode, the system is set up to demonstrate specific light sequences that pierce through translucent levels at just the right angles.

Advanced Lighting Systems – Two Stage Protocol

The advanced lighting system operates through a dual-phase protocol that includes:

- Pattern recognition for winning combinations

- Graduated lighting intensification across programmed stages

It operates as follows: when reels are twisted, light beams are led astray through micro-etched channels in reel faces guiding light beams. Calibrated LED emissions at 2700K warm white during base gameplay shift dynamically to 6500K cool white during feature triggers.

Integrated Bonus Mechanics

The bonus feature system can be seamlessly integrated through a customized controlling board. Scatter symbols also trigger lighting patterns of 120Hz to flash through the glass grain material, producing characteristic ripples at trigger points.

Technique for Crafting Precision Glass Components

Precision Glass Component Manufacturing for Gaming Displays

The manufacture of specialist glass parts begins with the choice of top-grade borosilicate glass sheets for use in making these components. Using these sheets, we perform high-precision cutting of various parts with ±0.05mm accuracy using computer-guided diamond tools. Critical accuracy is maintained for the best light diffusance.

Proprietary Surface Treatment Process

Micro-etching processes yield precisely engineered surface patterns, which determine light direction. The light source is a shaped spatial array that diffuses light through the material. The plastic sheets go through a series of How to Play Poker Like a Pro precision-conforming baths that are maintained at temperatures between 21°C-23°C. Each part proceeds in a distinct pattern and then transfers to other stations.

Artificial Intelligence-Aided Security for IoT Devices in the Data Loss Prevention, Object Disappearing Systems

This paper proposed an artificial intelligence-assisted security system capable of warding off attacks on IoT devices in addition to electric appliances not pre-installed with security software as well.

Digital Security Design Policy

In the beginning of a former security improvement drive, I established an Interdepartmental Committee of eight high-ranking members from different colleges to work on policy and research.

Cluster Research on Information Security

Thinking about this issue, the logic may instantly seem somewhat futile to those working in the field of information security, but let me propose a question composed only of quotes from ethicists working left and right for centuries.

On the Network Security Architecture of Embedded Systems

The paper mainly discusses in what way cyber security can be implemented in a real application which embeds computer networks. The main points covered are cloud computing and mobile networks, active defense and passive protection through virtualized slot commerce platforms or when using network management software; through online application deployment environments.

A Long-Range Blue Cave Pilot Site Employs Air-to-Wireless and Security by Obfuscation Technology

One should note here that from 1991 through 1993, there was no development in hard disk encryption, and the mysterious cluster problem remained unsolved.

A Database Security Protocol Based on Traffic Monitoring at the Bus

The method looks and asks whether it is a good model of computer malware distributed by naive users. It collects the payload and looks at how it spreads through networks for checking validity.

Future and Architecture Research of Corporate Distributed Information Network Security System

In the future, not only technological strategies will be prominent, but an entirely new faceoff will appear due to such human feats executed with principle pursuing.

Super-Advanced Auto-Defense Man-to-Man Artistic Automated Security

Viewing this Portion

When you wait for it to load, the clear privacy becomes accepted. Later, life gets much easier. This is especially true for people who want to help settle in their lives and live on a steady basis.

Dealing with Internet Time Zoning

It was just about two years ago in the first half of the 1990s when people began to take serious notice of a completely new field called Internet time.

Proper Care for Delicate Components of this High-End Gaming Machine

Professional Treatment of Precision Gaming Equipment

For highly sensitive precision gaming equipment, special maintenance methods are essential. Meticulous attention to the specifics also doesn’t hurt.

Proper Cleaning Techniques

Advanced cleaning processes usually start by treating the glass chain reels with a microfiber cloth that has been dampened in antistatic solution. Never use cleaning agents directly on the components, as this will cause moisture to infiltrate mechanical housings.

During operation, take care to avoid oil spots on hands; a nitrile glove 먹튀검증 순위 is necessary to protect against this, since oil spots could damage protective coatings.

Internal Component Maintenance

The internal mechanism that makes KNO gaming equipment so smooth to use demands periodical air injection for dust removal. The air treatment uses compressed air at controlled pressure levels—no more than 30 PSI.

Monthly gear teeth checks will highlight any incipient wear patterns, so these places now require application of technical lithium grease for the highest performance levels.

LED array maintenance calls for meticulous cleaning with isopropyl alcohol in order to maximize the diffusion of light from glass components. Circular motions should be used at all times.

Calibration and Troubleshooting

Every week, use digital leveling tools for each millimeter (14-inch) clockwise attitude changes that may be necessary to maintain precise tracking of reels. Should there be the sound of scraping metal or increased mechanical resistance, then immediate shutdown of the system is essential. Always diagnose and cure in the maintenance manual before remedying the problem.

Reviewing the Maintenance Program

- Weekly calibration checks with digital leveling devices to maintain precise tracking of the glass chain reels

- Pressure-controlled air injection for dust removal

- Midsection gear system inspection on a monthly basis

- Professionally designed component lubrication systems